Lathe turret

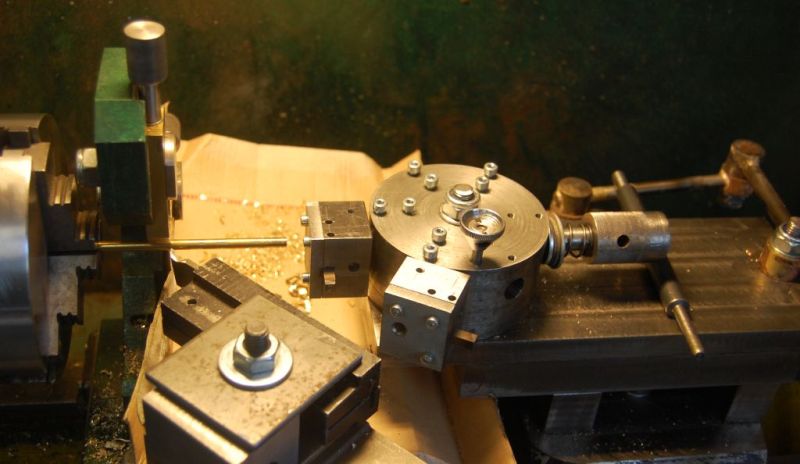

I have done earlier two times 80 spices of receiver wire end connector. This time I decided that these must be done easier and I made tool turret to my lathe in place of tailstock. There is now place for 6 tools, quick moment lever, movement max 130 mm. Only problem found so far is that tools on the turret will hit the tool post on the cross slide !

Here is pictures how connector are done now. The carton box on top of the cross slide is just collecting the small ready parts !

Here is pictures how connector are done now. The carton box on top of the cross slide is just collecting the small ready parts !

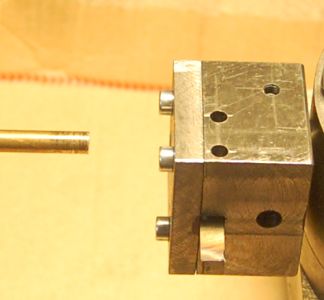

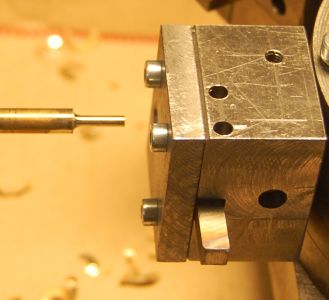

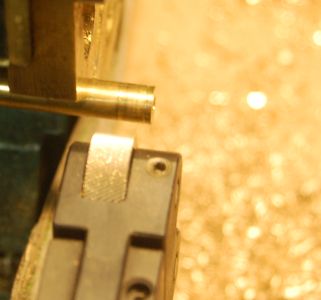

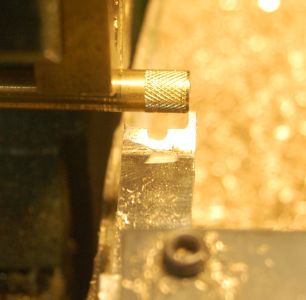

The cutting tools of turret have hole where the full diameter bar goes in and behind the steel sheet is the normal lathe cutting tool. In the hole there is adjustable stop.

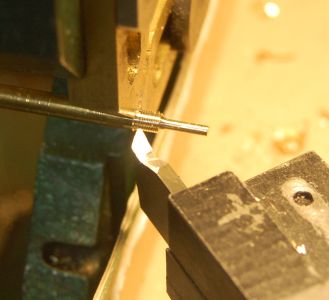

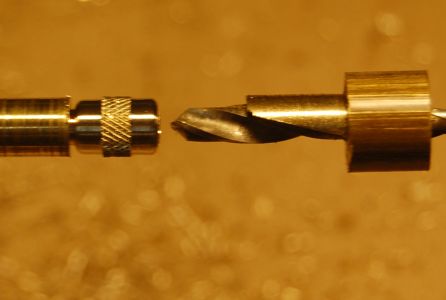

Making the pin starts with 5 mm brass bar, first cut to 2,3 mm pin, then 4,5 mm for tread, treading and cutting ready part in 45 decrease. Same cut makes the end for the next one to 90 decrease.

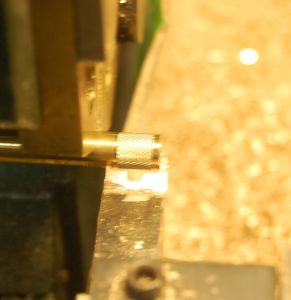

Making the brushing start with 6 mm brass bar, first knurling and then outside turning.

Drilling first with center drill, then hole for the tread, and for the wire.

Treading with second tap and bottoming tap.

Knurling the next one, when starting the outside turning, tool first cuts away the ready part and then the outside of the next one.

Brushing needs to be also second time on lathe, drilling the wire end turret. This removes also the extra brass left from cutting.

This is the result waiting tin layer of nickel, this time 100 spices ready.