Lathe

I bought German made Haager HD400 used lathe. Max piece is 250 x 400 mm. On top of the cross slide 155 x 400 mm.

Model is from -97 and it weight 120 kg.

Speeds from 120 to 2000 rpm.

Model is from -97 and it weight 120 kg.

Speeds from 120 to 2000 rpm.

I made table for lathe and drawers for tools under table.

I also changed the motor to get it work with frequency converter what I had. Converter is inside the grey box on the left end of the table. It is giving out 240 V and the original motor was for 400 V.

Now I can adjust speed easily from zero to 4000 rpm,

motor speed 0 - normal - 2 x normal.

Motor is 550 W, 1400 rpm (50 Hz).

Lathe is equipped with both metric and inch tread cutting gears.

I also changed the motor to get it work with frequency converter what I had. Converter is inside the grey box on the left end of the table. It is giving out 240 V and the original motor was for 400 V.

Now I can adjust speed easily from zero to 4000 rpm,

motor speed 0 - normal - 2 x normal.

Motor is 550 W, 1400 rpm (50 Hz).

Lathe is equipped with both metric and inch tread cutting gears.

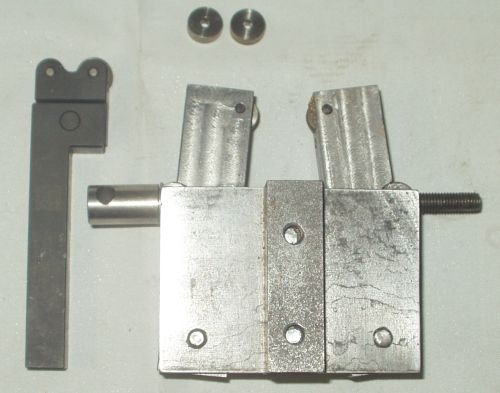

I have built small milling table to the lathe. Very useful for small parts from aluminum and brass.

I used the tool slide for table up/down slide and attached it with new holder to the cross slide.

Table is made from 20 mm thick aluminum and screwed to same place as tool post.

One additional screw holds the top of the table to tool slide.

This I do not use any more because I have milling possibility with my drilling machine.

I used the tool slide for table up/down slide and attached it with new holder to the cross slide.

Table is made from 20 mm thick aluminum and screwed to same place as tool post.

One additional screw holds the top of the table to tool slide.

This I do not use any more because I have milling possibility with my drilling machine.

With the lathe I did get set of 9 changeable inset tools na one small drilling tools have I bought later.

These soldered inset tools I have bought from second hand shop and their are Russian made.

The bigger cutting tool came with the lathe but it is too big so I have bought a smaller one.

The bigger cutting tool came with the lathe but it is too big so I have bought a smaller one.

These are high speed steel cutter part of them sharpened by me for the use of different items of phones, bought also from second hand shop and made in Russia.

I did get fixed centers, one live center and the bigger drill chuck with the lathe.

Small chuck I bought because bigger one takes drills from 3.0 up to 16 mm and I did need small ones also.

Adaptation from Morse 3 to Morse 2 is needed to get drill or mill to lathe mandrel with milling table.

Small chuck I bought because bigger one takes drills from 3.0 up to 16 mm and I did need small ones also.

Adaptation from Morse 3 to Morse 2 is needed to get drill or mill to lathe mandrel with milling table.

Here are mills, ones again from second hand shop and Russian made, biggest one is 20 mm and very good for flattening out things.

Center drill use is obvious.

Center drill use is obvious.

It seems that I have plenty of drills, but there is need for most of them.

I have drill for every 0.5 mm from 1.0 up to 15.0 and from that on for every 1.0 mm up to 23.0 mm.

The big set on the right is drills from 2.0 up 10.9 with 0.1 mm steps.

In the plastic is the smallest drills starting from 0.25 up to 2.0 mm.

I have drill for every 0.5 mm from 1.0 up to 15.0 and from that on for every 1.0 mm up to 23.0 mm.

The big set on the right is drills from 2.0 up 10.9 with 0.1 mm steps.

In the plastic is the smallest drills starting from 0.25 up to 2.0 mm.

For knurring I first bought the tools on the right, but soon I discovered that I need tools that is pressing the knurring wheels together so I did make the much heavier tools in the picture.

The most important tools for making repro parts for old Ericsson phones is the set of taps and dies of BA thread. My set covers from BA0 (6.0 mm) down to BA12 (1.3 mm).

I have also Metric set from 3.0 mm up to 12 mm,

and for phones there is a need also for 3/16 BSF and 3.5 mm Metric.

The drill chuck and the holders for dies I put to the headstock with the Morse 2 tapper, when making tread in the lathe.

This way the tread is straight every time.

Information about BA tread can be found on next two links:

I have also Metric set from 3.0 mm up to 12 mm,

and for phones there is a need also for 3/16 BSF and 3.5 mm Metric.

The drill chuck and the holders for dies I put to the headstock with the Morse 2 tapper, when making tread in the lathe.

This way the tread is straight every time.

Information about BA tread can be found on next two links:

I have now also UNC and UNF taps/dies size number 1 to 12. UNF size's are also used in Ericsson telephones like Skeleton. I also ordered UNS 10-30 which is needed for EB (Kristiani) line connection screws.

I did make piston type QCTP for my lathe. Now there is holder for parting tool, two boring bar holders 10 and 12 mm, 10 holders for different size tools in range from 8 to 16 mm. Also knurling tool has it's own holder.

These are also my first tools that I did blacken.

I am very happy with result, holders look good and their are working fine.

These are also my first tools that I did blacken.

I am very happy with result, holders look good and their are working fine.