Ericsson Spiral microphone

The working of Spiral (or Helical ) microphone developed by Lars Magnus Ericsson in 1879 and used in Ericsson phones since from 1880 to 1886-1887, then replaced with more stable carbon granule microphone, all ready in 1886 catalog both models. This carbon granule microphone patented 1888.

Trials with handset spiral microphone 1885, on 1886 carbon rod (tree rods) microphone and since 1888 with carbon granule microphone. In 1886 catalog, no telephones with handset.

This spiral microphone is based on Francis Blake microphone invented in 1878 and used in Bell's telephones. Blake microphone also needed very careful adjustment frequently, it has one loose contact between carbon and platinum. Blake's invention is based on professor David Edward Hughes carbon rod microphone studies.

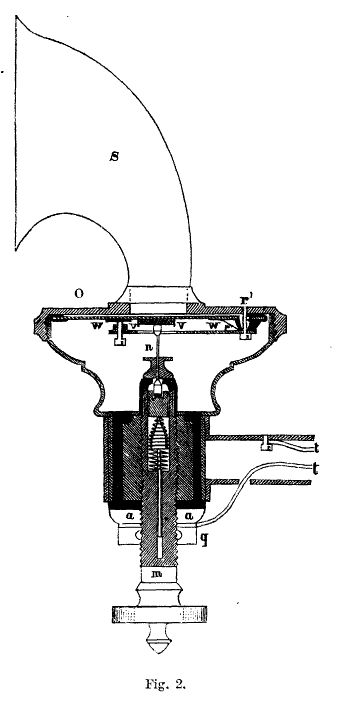

Figure 2 is showing the section view of Ericsson spiral microphone. Adjusting screw m turns in a nut q which is isolated from microphone casing. Top of screw has drilling where the spiral spring is. Spring is holding brass cup, which has platinum button in bottom. Top part of microphone case O has the mouthpiece and elastic disk WW fastened. Carbon piece vv is detached to disk WW. Between the carbon vv and brass cups plating bottom sits bar n, bottom of bar has carbon piece and top has platinum button. Spiral spring is pushing bar against carbon vv, force can be adjusted with screw m. Current from local battery comes in via wire t to nut q, screw m and to bar n, crossing it's both contacts and then going to disk WW, screw r, microphone case O and via wire t to primary of speaking transformer and back to local battery.

Trials with handset spiral microphone 1885, on 1886 carbon rod (tree rods) microphone and since 1888 with carbon granule microphone. In 1886 catalog, no telephones with handset.

This spiral microphone is based on Francis Blake microphone invented in 1878 and used in Bell's telephones. Blake microphone also needed very careful adjustment frequently, it has one loose contact between carbon and platinum. Blake's invention is based on professor David Edward Hughes carbon rod microphone studies.

Figure 2 is showing the section view of Ericsson spiral microphone. Adjusting screw m turns in a nut q which is isolated from microphone casing. Top of screw has drilling where the spiral spring is. Spring is holding brass cup, which has platinum button in bottom. Top part of microphone case O has the mouthpiece and elastic disk WW fastened. Carbon piece vv is detached to disk WW. Between the carbon vv and brass cups plating bottom sits bar n, bottom of bar has carbon piece and top has platinum button. Spiral spring is pushing bar against carbon vv, force can be adjusted with screw m. Current from local battery comes in via wire t to nut q, screw m and to bar n, crossing it's both contacts and then going to disk WW, screw r, microphone case O and via wire t to primary of speaking transformer and back to local battery.

Figure 3 is showing the schematic of this type telephone: K-P is the microphones carbon (Kol) and platinum (Platina) contacts, K (Klock) bell ringer, T (Telefon) receiver, B (Batteri) local battery, R speaking transformer, i (inductor) ringer generator, L line connection, J (Jord) ground connection and H (Häfstågen) bracket where receiver is hanged when telephone is not in use.

There is a mistake in drawing, the contact for primary circuit is working opposite as it should !!

There is a mistake in drawing, the contact for primary circuit is working opposite as it should !!

Pictures are taken and text is translated from "Nordisk familjebok / 1800-talsutgåvan. 15. Socker - Tengström 1891" that can be seen on Project Runeberg web pages.

This is how looks my repro part for spiral microphone, casing ready internal small parts missing.

Membrane now in place with it's holder and the coal detached to membrane.

Below are the moving parts for the microphone.

Note the millimeter scale beside.

Below are the moving parts for the microphone.

Note the millimeter scale beside.

Parts are very small and had to be done almost with the clock making accuracy.

Now waiting the platinum to the contact points.

Now waiting the platinum to the contact points.

Here is my made side by side with the original one. Looks pretty same.

Original one is missing the locking nut and taken out from holder.

Original one is missing the locking nut and taken out from holder.

This is how it looks internally when ready. Contact points are now platinum plated and the microphone is test to be working. Not very sensitive but anyway working as transmitter.

Making curvy mouthpiece from one piece of brass sheet is much harder than expected. Just making the internal mould for it is hard. Cutting the sheet to correct shape, I mean finding the correct shape needs trials. Soldering it together with phosphore copper is much harder what you can expect.

Making curvy mouthpiece from one piece of brass sheet is much harder than expected. Just making the internal mould for it is hard. Cutting the sheet to correct shape, I mean finding the correct shape needs trials. Soldering it together with phosphore copper is much harder what you can expect.