Column Drill

I did bay an old Strands column drill, put it in to spices, painted totally, all bearings changed, some broken part done and now it looks like new.

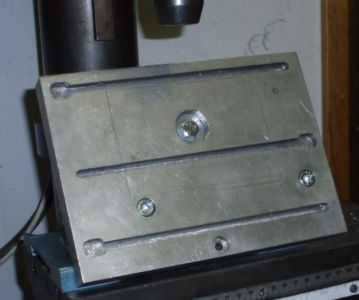

An old milling table added for small milling jobs.

Frequency inverter added to get more choices for speeds.

Motor had two speeds and gearbox only to gear's.

Now freely adjustable !

An old milling table added for small milling jobs.

Frequency inverter added to get more choices for speeds.

Motor had two speeds and gearbox only to gear's.

Now freely adjustable !

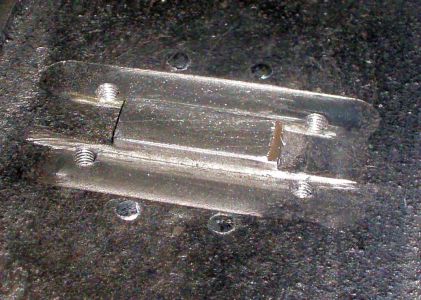

For milling I did buy ER-chuck with Morse 3. Collect set is from 2 to 20 mm, ten collects.

It did need some thinking before I started making the parts for locking to drill spinel.

Now it lock firmly to drill spinel.

It did need some thinking before I started making the parts for locking to drill spinel.

Now it lock firmly to drill spinel.

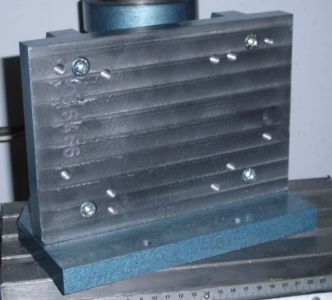

I made an tilting table for milling/drilling from two train brake pad. Just center part of bad used and it did need just lockable hinge and some holes !

Lowest pisture shows also the parts of brake bad that are cut away.

Lowest pisture shows also the parts of brake bad that are cut away.

This vertical stand is made from casted steel sheet like counterweighs of an old washing machine.

First bigger milling job with my drill/mill.

First bigger milling job with my drill/mill.

I made also an simple turn table mainly for drilling, but can be used also for milling with hand turning. I can use here the chuck from my lathe. The base for turn table is a bottom of big milling vise base found from junkyard.

The cross table screw nuts ware wean to have too much clearance one 0,3 and other even 0,7 mm. The problem there was that their where machined directly to the cast steel. Needed total removal and making new holders for new bronc nuts. Looking now nice and the moment was not reduced at all. Clearance now less than 0,05 mm !